As an internationally active clutch specialist, KM offers development competence of the highest standard for all types of clutch. KM clutches are subject to the strictest test criteria and undergo all important quality checks. We are a company certified according to DIN EN ISO 9001 – all our processes are clearly defined.

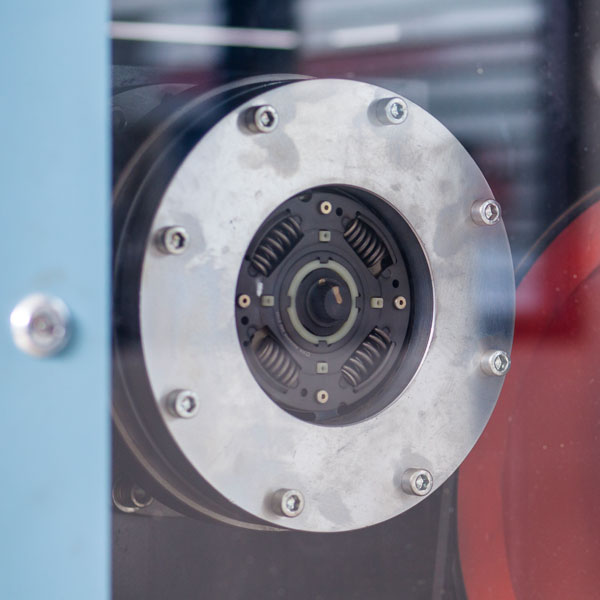

We only supply new parts in OE matching quality. KM sets standards in the field of quality from as early as the clutch development stage. Only high-quality components are used in the manufacturing processes at our partners' facilities. Clutch linings, diaphragm springs, torsion springs, washers, cover plates and cast parts are all sourced from leading manufacturers.

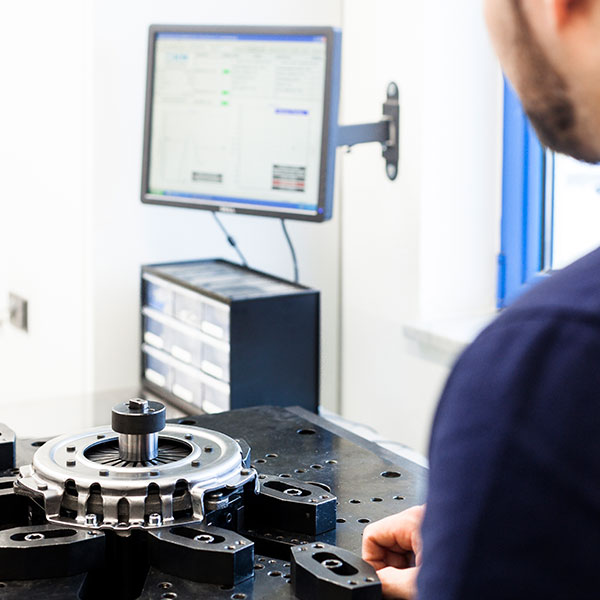

Ably assisted by a measuring robot, we check all important dimensions to an accuracy of one thousandth of a millimetre in our KM test laboratory in Durmersheim, in order to ensure a perfect fit. This precise checking is not only used during the development of new products; it also forms an integral part of the incoming goods inspection.

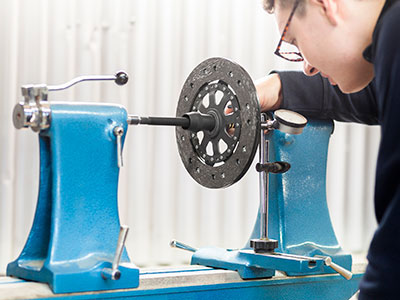

To ensure flawless function and excellent driving comfort, special test beds are used for all clutch components. Measuring programs developed internally ensure the adherence to tight tolerances. All clutch discs and clutch pressure plates pass durability and performance checks through in-house test benches to guarantee consistent quality.

Quality begins for us already with the packaging: Clutches from KM are delivered in specially manufactured, sturdy packaging that not only includes KM high-performance grease for lubricating the connection between hub and transmission shaft, but also a special service flyer and instructions for quick, technically correct installation.